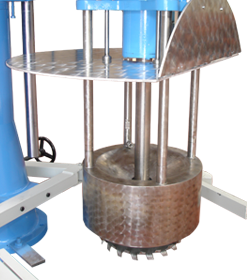

| Hi-Shear-RotorStator Mixer(Silverson Type Mixer) |

| High Shear Batch Mixer, Emulsifier, Homogenizer, Solubiliser, Disperser and Solids Disintegrator |

| Features and Benefits | ||||||||||

|

| Multi-Stage Mixing/Shearing |

Homogenizer – (High Shear Mixer Rotor / Stator Mixing Impeller)The key to creating finest emulsion is to creat finest possible droplet size. The more the energy in the mix, the smaller the droplet size in emulsion, creating fine emulsion.high shear batch mixer doesn’t simply mix; it emulsifies, homogenizes, solubilizes, suspends, disperses and disintegrates solids. Each mixer, with its precision-engineered Silverson rotor/stator workhead, far outperforms conventional mixers, cutting processing times by up to 90%, improving quality, product consistency and process efficiency.

|

|

|

|

|

| STEP 1 | STEP 2 | STEP 3 | |

| The high-speed rotation of the rotor blades within the precision-machined mixing workhead exerts a powerful suction, drawing liquid and solid materials upwards from the bottom of the vessel and into the center of the workhead. | Centrifugal force then drives materials towards the periphery of the workhead where they are subjected to a milling action in the precision-machined clearance between the ends of the rotor blades and the inner wall of the stator. | This is followed by intense hydraulic shear as the materials are forced, at high velocity, out through the perforations in the stator and circulated into the main body of the mix. | |

| The materials expelled from the head are projected radially at high speed towards the sides of the mixing vessel. At the same time, fresh material is continually drawn into the workhead maintaining the mixing cycle. The effect of the horizontal (radial) expulsion and suction into the head is to set up a circulation pattern that minimizes aeration caused by the disturbance of the liquid’s surface. |  |

||

| ROTOR / STATOR MIX HEAD TYPES | |||

|

|

|

|

| The Wetting Head (A) or Disintegrating Head, with large round holes works best for general purpose mixing. This is the most versatile of all the heads, giving an exceptionally vigorous mixing action and rapidly reduces the size of large particles.. Ideal for general mixing applications, its uses also include the disintegration of solids and the preparation of gels and thickeners, suspensions, solutions and slurries. | The Slotted Head (B) provides the most popular combination of high shear and efficient flow rate. It is ideal for emulsions and medium-viscosity materials.For the disintegration of fibrous materials such as animal and vegetable tissue, as well as the disintegration and solubilization of “elastic” materials such as rubbers and polymers | The Fine Hole Head (C) provides the highest shear possible − at the expense of a slower flow rate. It is most suitable for low-viscosity emulsions and fine dispersions.Provides exceptionally high shear rates ideal for the rapid size reduction of soluble and insoluble granular solids. It is also suitable for the preparation of emulsions and fine colloidal suspensions | |

Inquire About this Product:

[contact_form]

|

|  |

|  : +92-321-8484004 |

: +92-321-8484004 |  : info@kew.com.pk |

: info@kew.com.pk |  : kew.sales

: kew.sales