Vacuum Mixer Emulsifier,Homogenizer, Disperser

KEW has been a leading partner in process engineering technology for the pharmaceutical, cosmetic, food and chemical industries. Our innovative and broad range of machines are […]

KEW has been a leading partner in process engineering technology for the pharmaceutical, cosmetic, food and chemical industries.

Our innovative and broad range of machines are used in a broad variety of applications, from ketchup and mayonnaise production to vacuum processing of pharmaceutical products.

FEATHRE & BENEFITS

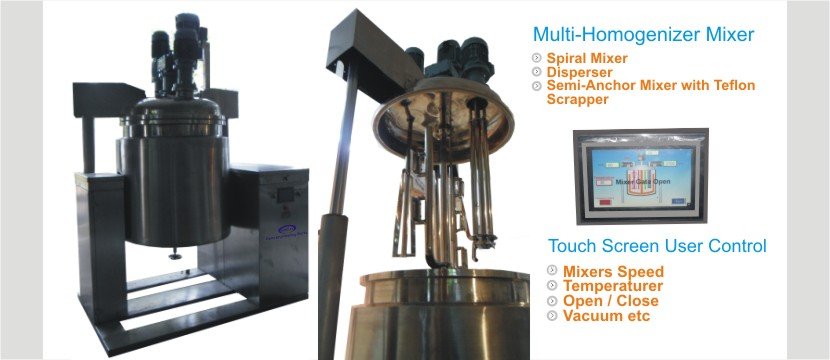

- Intensive Mixing by means of semi-anchor mixer and efficient scraper system.

- Intensity of homogenizing can be regulated by means of adjustable grip between rotor and stator.

- Optimal vertical mixing as well as quick deaeration by means of mixing spiral.

- Clean and aseptic working as no seals in reach of the product.

- Clean air-free work due to vacuum application and closed system.

- Drawing-in of raw material directly into the turbine of the homogenizer by means of special sucking device.

- Vessel with double jacket in stainless steel inside and outside for heating and cooling by means of steam or electricity heated bath.

|

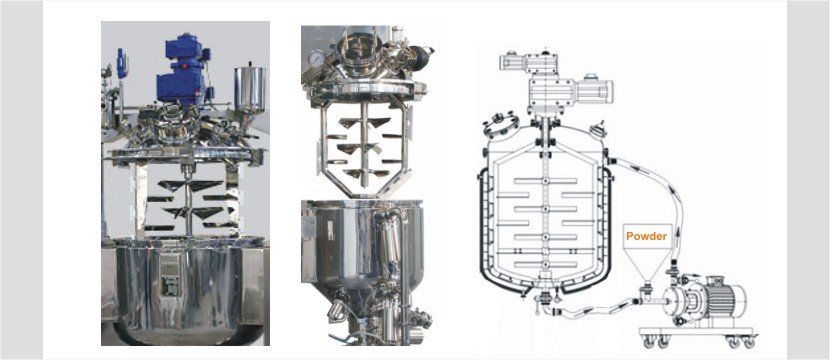

| MIXING VESSEL DETAIL |

| The mixing vessel is manufactured entirely in stainless steel 304 / 316, inside as well as outside. The inside is high gloss polished, all welded seams are dressed and polished, the outside is matt polished.The vessel is connected to the robust machine frame (the structure and configuration of the mixer depends on its size, application and sometimes customer requirements.) and emptied through a bottom valve. |

| Vacuum Cover |

| The machine has a vacuum and pressure resistant cover; Vacuum up to . The cover is equipped with all necessary vacuum and pressure fittings. The cover is moreover equipped with a light and sight glass as well as with a lamp. The necessary pressure clamps are mounted on the cover and part of our standard supply. The cover is also equipped with a device which feeds fluid or powdery raw material directly into the homogenizer. The cover is provide with a spring loaded hinge and can be opened with one hand. |

| Machine Frame |

| The machine frame is made of rectangular profile structure steel and sprayed with blue or white paint. Other colours can be supplied on upon demand. The vessel is fixed on the machine frame and the latter does not have to be fixed to the floor. |

| Control Panel |

| The machine is provided with a control panel box which contains all electrical functions. |

| Temperature Control |

| The standard machine is equipped with a thermometer in the product area, but a temperature control can be supplied. The latter consists of a temperature probe in the product area which commands a motor valve at the entrance socket of the double jacket by means of a requlator. |

|

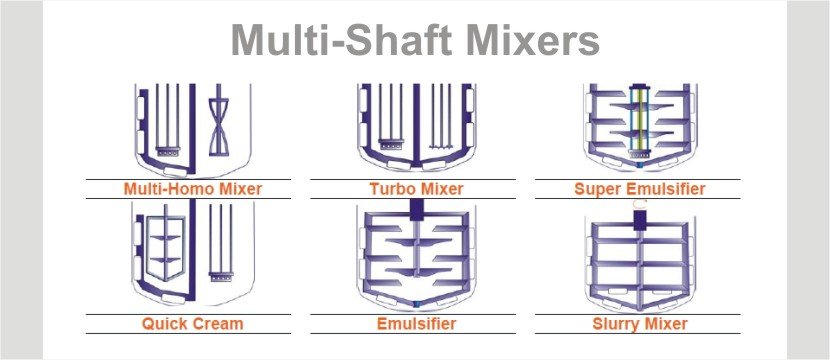

| MIXING SYSTEM DETAIL |

| Single, Double, Tripple Mixing Impellers & Optional External Inline High-shear Mixer |

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|  |  |

| Emulsifier | Multi – Homogenizer Mixer | Slurry Mixer |

| Quick Cream | Turbo Mixer | bg |

Inquire About this Product:

[contact_form]