INDUCTION SEALING – CONTINUOUS

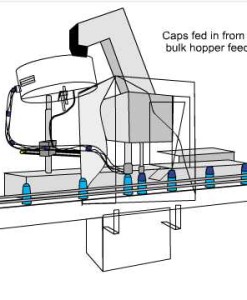

The machine is suitable for PE Laminated Aluminum Foil/ Lid sealing of Plastic or Glass container.

For Pharmaceutical, Cosmetic, Chemical etc industry.

FEATURES:

- Continuous induction Heating

- Air Cooled

- Variable Speed

- Over-voltage, Over-current automatic protection, safe and reliable

- Quick sealing speed, suitable to mass product production.

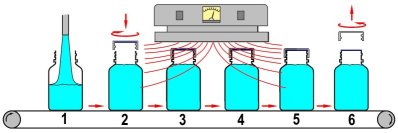

WORKING:

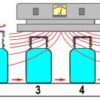

Continuous induction Laminated Aluminum Foil Sealing Machine utilizes electromagnetic principle, producing instant high heat, which can melt and seal an aluminum foil to a bunghole. It features excellent wet-proof, fungus-proof and imitation-proof and an extension of preservation cycle. It can not be used at metal bottle body and bottle cap. And this product is accord with GMP Standard,all outside material is Stainless Steel, and there are including Table Sytle, With Assemble Line Style and Without Assemble Line Style, it can work not only independently but also with Production Line.With high sealing efficiency, easy operation, and the sealing speed can be adjusted at will, with high accuracy. Suitable for various sealing of pharmaceutics, daily chemicals, foodstuffs, cosmetics, pesticide and special trades.

Inquire About this Product:

[contact_form]

|

|  |

|  : +92-321-8484004 |

: +92-321-8484004 |  : info@kew.com.pk |

: info@kew.com.pk |  : kew.sales

: kew.sales